Have you ever wondered how exactly chocolate is made?

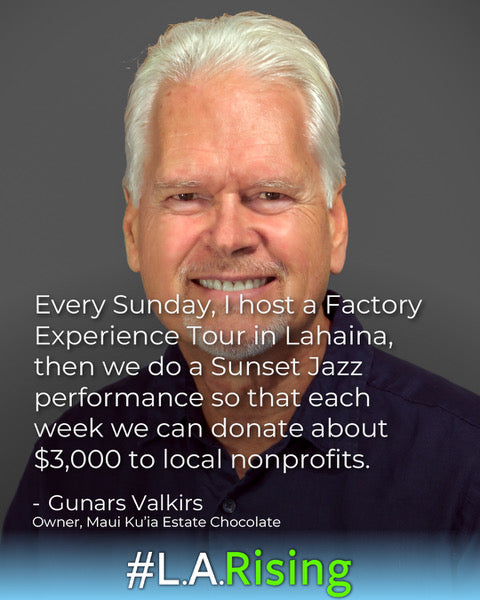

Here at Ku'ia, we only use three ingredients when making our dark chocolate: cacao beans, cocoa butter, and sugar. There is a very specific way that the beans need to be processed to be turned into chocolate, and luckily our VP of Chocolate Operations Dan O'Doherty and our CEO Dr. Gunars Valkirs have perfected the process.

1. Use high quality cacao

Similarly to coffee, the quality of the cacao fruit makes all the difference. It is exactly why we only work with cacao that Dan has personally chosen.

2. Fermentation

Not many people know that after picking cacao pods, the beans need to be stripped and then properly fermented. We ferment our beans in wooden boxes covered with banana leaves.

3. Drying the beans

After the beans are fermented, they are dried out on large screens, similar to how coffee is dried.

4. Roasting

When it is time to begin the chocolate making process, the beans are roasted to the perfect temperature and dehydration level.

5. Winnowing

The beans are then transferred into a winnowing machine. This machine essentially cracks the beans open and separates the outer shell from the heart of the bean itself, which is used to make chocolate. The result is known as cacao nibs.

6. Grinding Nibs

The cocoa nibs are then pushed through another machine that fully pulverizes the nibs into a fine particles, resulting in what is referred to as cocoa mass.

7. Ball Mills

At this stage, chocolate really begins to take form for the first time. The cocoa mass is placed inside a huge mill filled with thousands of tiny metal balls. This is the part of the process where cocoa butter and sugar are added. The balls swirl around and break up the particles as well as mix them together.

8. Conching

The chocolate mixture is transferred from the ball mills into a large vat called a conch. The mixture is further mixed for several hours to refine particle size and chemical structure of the chocolate.

9. Tempering

After the chocolate has been mixed within the conch, it is time to temper the chocolate. Tempering is the process of manipulating the crystalized structure of the chocolate. Well tempered chocolate has a wonderful texture to it and pleasant "snap" when it breaks. This is done through heating and cooling the liquid chocolate.

10. Molding

The final state of chocolate making is molding! We use a machine to mold our chocolate into our signature Ku'ia squares. It is the large machine that you'll see when you look through the window into our chocolate factory from our retail store.

Want to see more?

You can view a behind the scenes look at our chocolate making process in the "Virtual Tour" highlight on our Instagram account.

If you want to learn more about the process, book a guided chocolate tasting!

Leave a comment (all fields required)